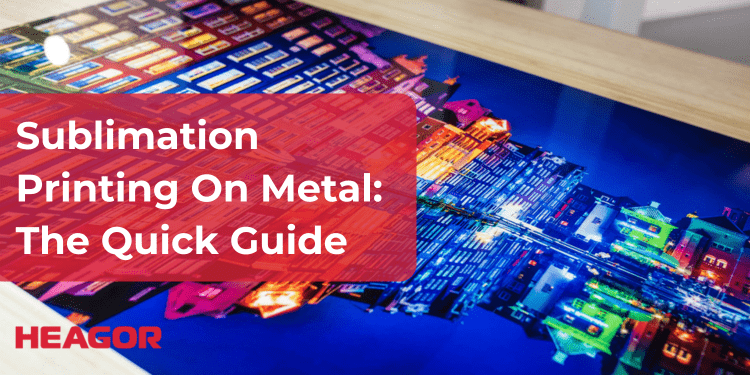

Sublimating Printing on Metal has become a go-to choice in different sectors where it turned out to be the definitive selection for custom art pieces along with eye-opening signage and promotional items.

The global dye-sublimation printing market is projected to expand at a CAGR of over 12.35% from 2021 to 2029. The market, which was just above USD 8.83 billion in 2020, is anticipated to surpass USD 25.18 billion by 2029. (1)

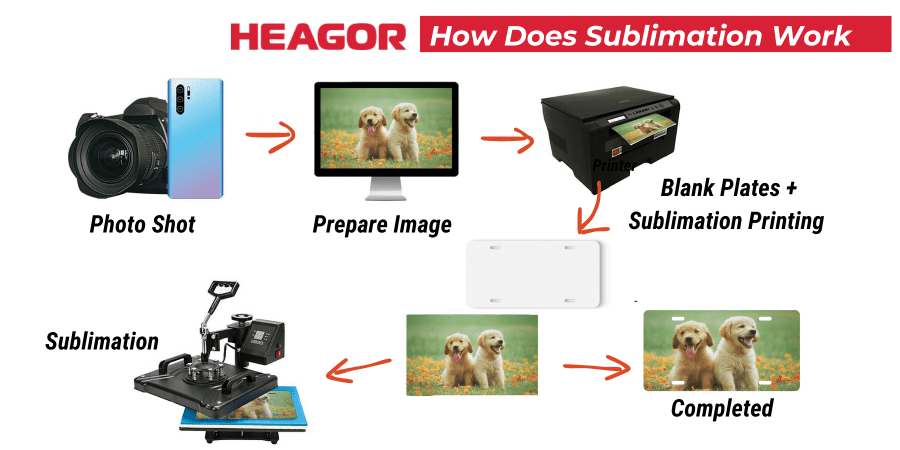

Section 1: What Is Sublimation Printing?

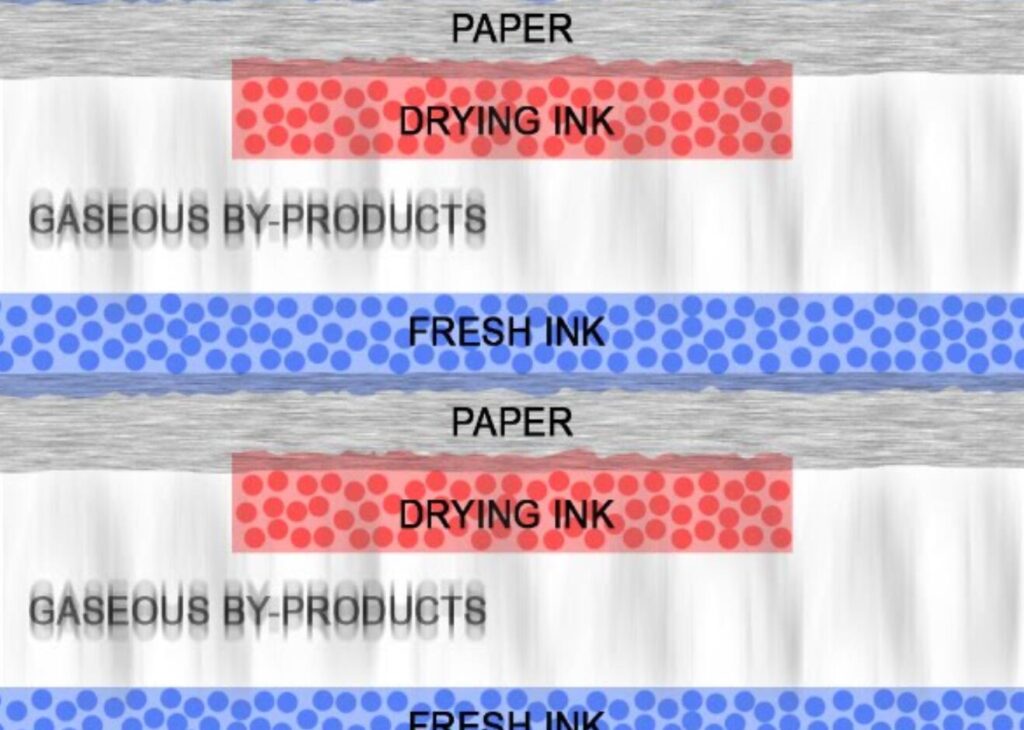

Sublimation printing is an amazing technique in which dye is printed onto fabric using heat.

Once this gas infiltrates the material surface, it immediately transforms into a solid and then impregnates itself with the fibers.

Section 2: Why Choose Metal For Sublimation Printing?

Advantages of Using Metal for Thermal Sublimation Printing

1. Heat Resistance

Metal substrates can withstand high temperatures without any deformation or damage. This is especially good for areas where other materials wouldn’t do well such as near machinery or the hot climate.

2. Corrosion Resistance

Metals are naturally resistant to corrosion especially aluminum (2). This makes metal prints ideal for being used as wall art which can last a lifetime even in coastal areas.

3. Lightweight

There can have surprising strength in some metals like aluminum.

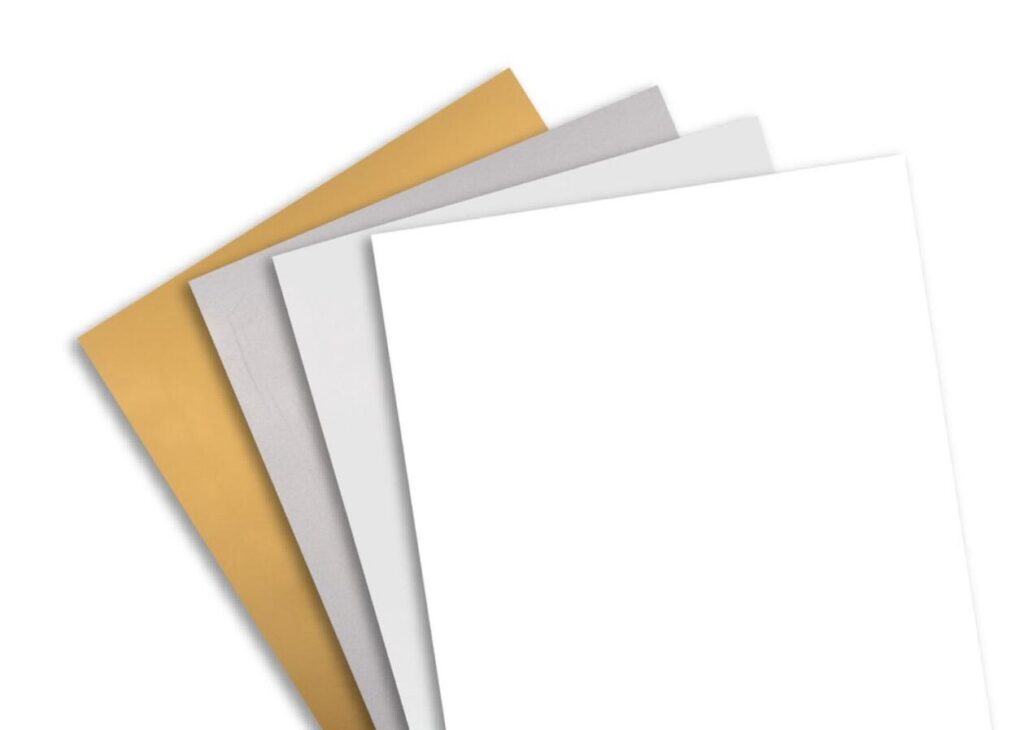

Common Types of Metals Used:

Aluminium

It is a light, rigid and also a fantastic medium for sublimation printing.

It has a smooth surface that gives the prints a high-definition quality and is resistant to rust and corrosion making it ideal for outdoor applications.

Other Metals

Some other metals include Stainless Steel and Brass which are also accepted in the world of metal.

Brass gives a vintage look, and stainless steel is more crossion-resistant (3). Additionally, these metals are more rare because they come with greater costs and difficult to print properties.

Aesthetic and Functional Advantages

- High Gloss Finish

- Custom Shapes and Sizes

- UV protection

- Reflective Quality

- Less Maintenance

Section 3: Step-By-Step Process Of Sublimation Printing On Metal

Step 1. Design Creation

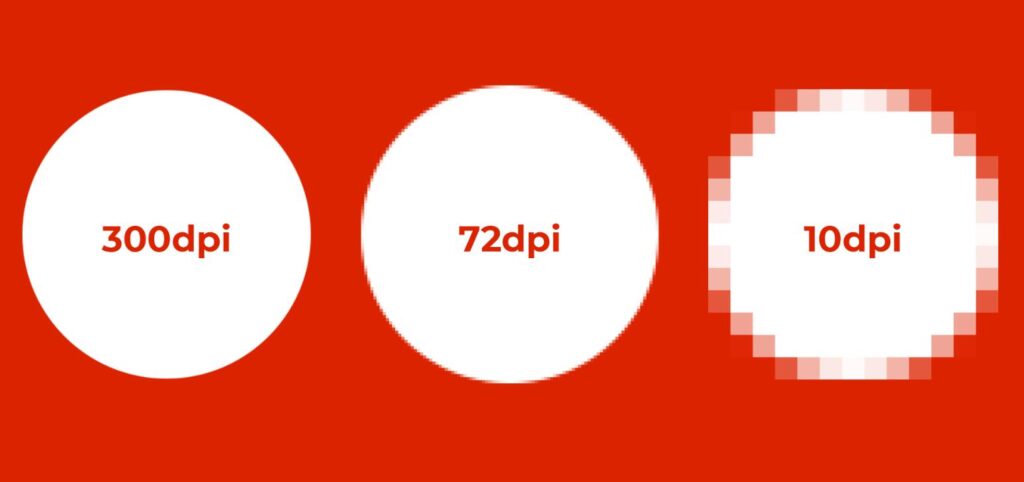

Design your layout using graphic design software such as Adobe Photoshop or Illustrator. To ensure the best quality print make sure your image is high resolution of 300 DPI min (4).

The most important thing in this case is that before you print, make sure to mirror your picture horizontally. This mirroring ensures that the design appears correctly when transferred to the metal, maintaining the integrity of text and visuals.

Step 2. Printing the Design

After you finish the design, just print it on sublimation transfer paper.

A sublimation printer full of high-quality sublimation ink prints the actual design on transfer paper. The special characteristic of sublimation ink is it turns into gas when heated so as to be bonded with the polymer coating on metal.

Step 3. Preparing the Metal

You will need a metal blank that makes a strong basis for sublimation print.

Prior to transferring always ensure you wipe your metal blank with a lint-free soft cloth to remove dust oil and even fingerprints.

Step 4. Transferring the Design

Place the print transfer paper over the metal blank face down.

Secure the paper with some heat-resistant tape so that it is in place and does not shift around or go askew during transfer. Proper placement and stability of the transfer paper is very important to avoid any misaligned images or lines and then some smudging when it cures.

Step 5. Heat Pressing

Always refer to the instructions of your heat press, but most are set around 350 to 400 degrees and for about a minute (5). Every material could have its settings so we need to check the manufacturer’s instructions.

Once the metal blank is secured with transfer paper and inserted into the heat press, apply even pressure before pressing.

Step 6. Cooling and Finishing

Once the heat press cycle finishes, you can carefully remove the metal blank and set it aside to cool. Be careful, the metal will be very heated so you can burn yourself.

After cooling, peel off the transfer paper to expose your non-fade coloring image.

Equipment and Materials Needed for Sublimation Printing on Metal

- Sublimation Printer: A printer specifically designed for sublimation, such as the Epson SureColor series or Sawgrass printers.

- Sublimation Ink: This is a special ink that turns into gas under heat. It is very important for the sublimation process.

- Sublimation Transfer Paper: The paper used to print your design, and hold the ink that vaporizes when it is heated.

- Heat Press Machine: It applies heat and pressure in a consistent manner. Although sublimation printing does not need a lot of pressure Clamshell and swing-away can be used.

- Metal Blanks: These are sheets already coated usually aluminum and ready for sublimation printing.

- Transfer Paper Tape: It is a high-temperature tape needed to secure the transfer paper over a metal blank.

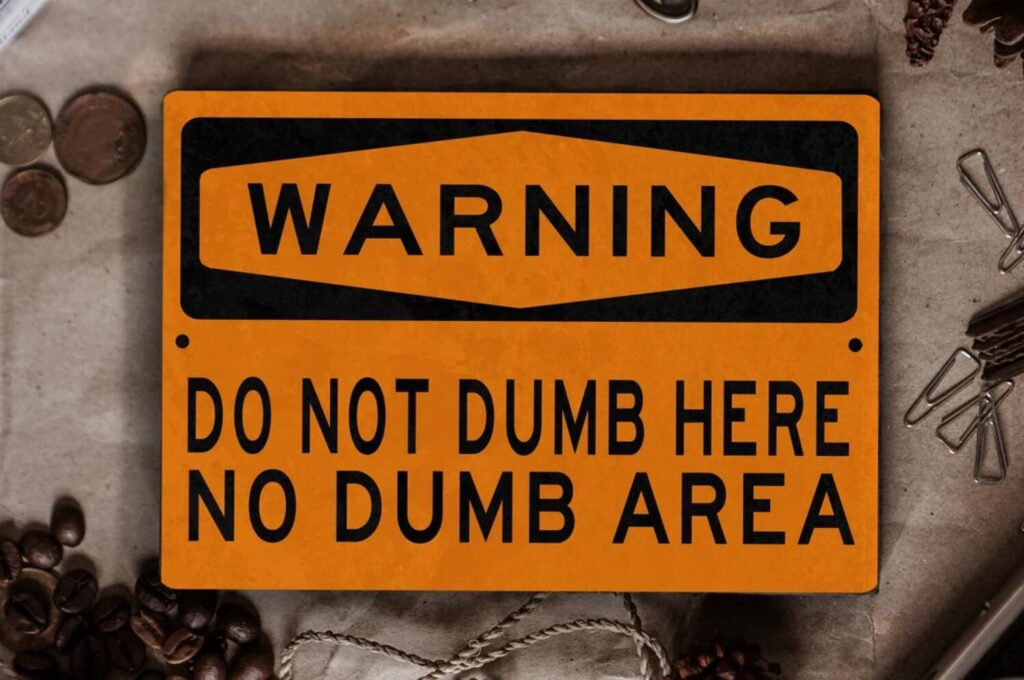

Section 4. Applications Of Sublimation Printing On Metal

1. Custom Signage

More and more designs work both indoors and outdoors.

They are perfect for business signage or wayfinding signs, informational displays and much more. The high-definition vivid colors draw the eye and ensure that visitors can read them from far distances.

2. Promotional Products

With sublimation printing metal items like business cards and nameplates or promotional merchandise last nearly forever.

3. Art Pieces and Photo Prints

Sublimation printing on metal is often used by artists and photographers to print high-quality prints of their work. Vibrant colors and high shine bring visual appeal to art pieces and photographs, which makes them perfect for galleries, exhibitions, and personal archives.

4. Industrial Labels and Tags

Sublimated metal labels and tags are used for equipment identification, safety signs, and product labeling.

Section 5. Tips For Getting The Best Results

1. Practical Advice on Design Considerations

Bright colors will pop even more with sublimation printing. Keep all images high-resolution minimum 300 DPI to make sure your prints are not pixelated.

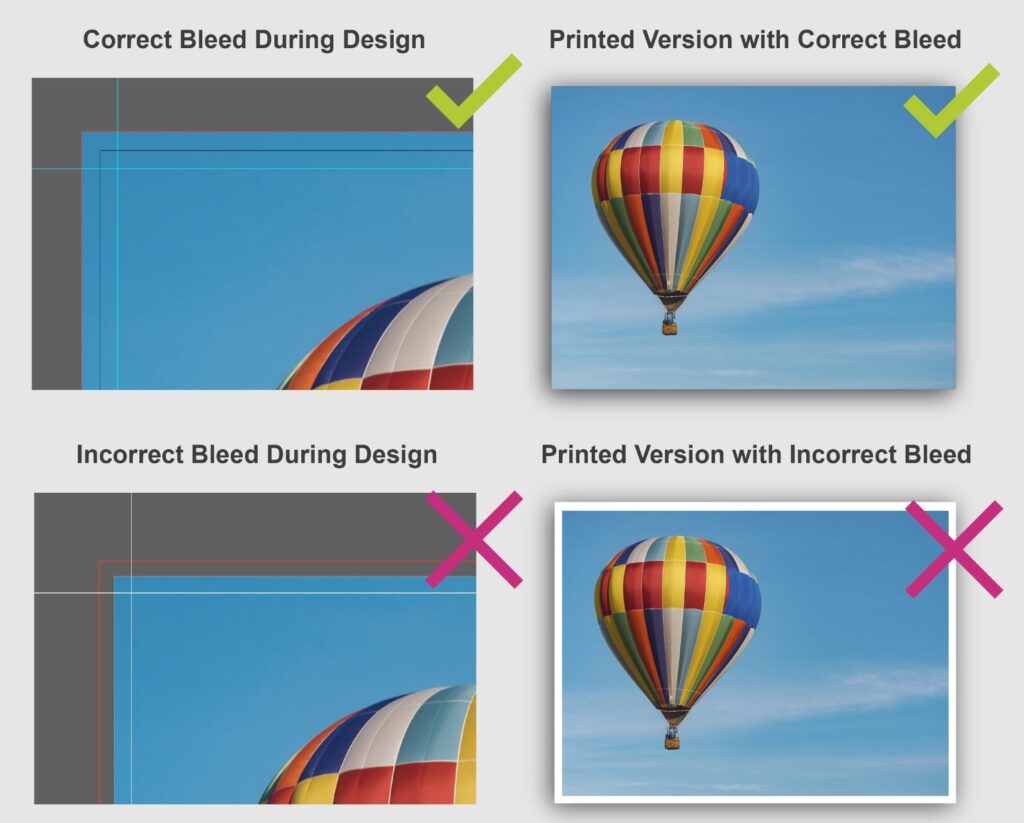

Be sure your design is the size of but not larger than the metal blank you are working with, and allow room for bleed along all edges to ensure your entire design prints properly without missing sections.

2. Ways to Avoid Common Issues

To prevent ghosting, secure the transfer paper super tightly to your metal blank with heat-resistant tape to avoid moving/sliding around during the transfer.

Use the proper temperature and pressure settings recommended by the manufacturer to avoid fading also preheat slightly your metal blank before adhering to your transfer paper, that way it will allow good ink adhesion.

3. Importance of Using Quality Materials and Equipment

You will need to use the right kind of metal and have well-maintained equipment in order to get great sublimation prints on metal.

Temperature and humidity fluctuations can influence print results so maintain a stable printing environment. Use the most advanced software settings and custom color profiles such that your designs exactly resemble in print.

Section 6. Challenges In Sublimation Printing And How To Overcome Them

1. Color Shifts

- Problem: The color you see on your screen can look different from those on the computer screen.

- Solution: Regularly calibrate your printer and monitor. Print with ICC color profiles customized for your specific printer and inks to accurately reproduce colors. Print sample pages to help you adjust those color settings according to your requirements.

2. Ink Bleeding

- Problem: Ink bleeding occurs when colors spread beyond their intended boundaries, resulting in blurry images.

- Solution: Check that your heat press applies the right amount of pressure. Excessive pressure can cause the ink to bleed. Make sure that the substrate is properly coated and high-quality transfer paper.

3. Ink Saturation

- Problem: Over-saturation of ink can lead to dark spots and uneven color distribution.

- Solution: Change the ink settings on your printer so it prints softer with less saturation. This can be helped in part by using better sublimation paper, which absorbs the ink evenly Also, you can send a test print to see if it works fine before the final touches.

Final Thoughts

By understanding the process, using quality materials, and following best practices, you can achieve impressive results in both appearance and longevity. This guide has provided you with a solid foundation on the basics of sublimation metal printing, preparation tips, and practical applications.

References:

1.https://exactitudeconsultancy.com/reports/22310/dye-sublimation-printing-market/

2.https://www.sciencedirect.com/topics/engineering/aluminum-corrosion#:~:text=The%20corrosion%20resistance%20of%20aluminum,increases%20at%20the%20elevated%20temperature.

3.https://polishedmetals.com/brass-vs-stainless-steel/

4.https://www.adobe.com/uk/creativecloud/photography/discover/dots-per-inch-dpi-resolution.html#:~:text=If%20an%20image%20has%20a,for%20printing%20high%2Dquality%20images.

5.https://uscutter.com/content/PDFs/5in1_heat_Press_Users_Manual.pdf